ICCP Anodes

After extensive research and development, we have designed the new generation ICCP anode to cope with any calculated pressure fluctuation on ship’s stern area.

For each individual speed and power we can calculate these pressure fluctuation.

Recently the size of container ships has increased, however the draft of such large ships remains the same(12.5 ~13.5).

Accordingly this will increase the load of propeller blade as well as the amplitude of pressure fluctuation to the stern anode positioned area.

The bilge vortex of such large container ship is extremely stronger and it’s trace line is more likely closer to the stern anode and this may hit the surface mounted linear anode.(after anode)

In addition, due to the continuous, regular pressure fluctuation and the effect caused by bilge vortex, the anode body made by epoxy resin will be easily damaged and holding nuts of anode may easily loosen and we therefore predict some hair cracks to the cable.

So, the sea water may be sucked into the ship’s inside and sometime lost the anode totally.

ITTC(International Towing Tank Conference) (1) has recommended around 8kpa as a maximum pressure fluctuation but some model tests of 6000 TEU container ships shows it’s value appx 11kpa or more.

The newly constructed anode is very strong and compact and is guaranteed sea water leak proof even if pressure fluctuation around 8~15kpa or more.

We recommend that the specially designed with steel plate back up, under water replaceable anode is to be fitted so that the anode can be replaced anytime without dry docking.

Recently the size of container ships has increased, however the draft of such large ships remains the same(12.5 ~13.5).

Accordingly this will increase the load of propeller blade as well as the amplitude of pressure fluctuation to the stern anode positioned area.

The bilge vortex of such large container ship is extremely stronger and it’s trace line is more likely closer to the stern anode and this may hit the surface mounted linear anode.(after anode)

In addition, due to the continuous, regular pressure fluctuation and the effect caused by bilge vortex, the anode body made by epoxy resin will be easily damaged and holding nuts of anode may easily loosen and we therefore predict some hair cracks to the cable.

So, the sea water may be sucked into the ship’s inside and sometime lost the anode totally.

ITTC(International Towing Tank Conference) (1) has recommended around 8kpa as a maximum pressure fluctuation but some model tests of 6000 TEU container ships shows it’s value appx 11kpa or more.

The newly constructed anode is very strong and compact and is guaranteed sea water leak proof even if pressure fluctuation around 8~15kpa or more.

We recommend that the specially designed with steel plate back up, under water replaceable anode is to be fitted so that the anode can be replaced anytime without dry docking.

Feature and Benefits

- Fully split, underwater replaceable within 1 or 2 hours.

- Robust construction yet extremely compact sized for massive external impact

- Simplified installation procedures reduce costs of anode replacement in the water.

- Innovative sealing system ensures the perfect water tight.

- Semi-permanent life time of anodes

- Ensures damage free against large pressure fluctuation (8 ~ 15 Kpa)

Application

- CONTAINER CARRIER

- ICE BREAKER

- SEINER

- BULK CARRIER

- CRUISER

- LNG CARRIER

- NAVAL SHIP

- PRODUCT CARRIER

- OFFSHORE PLANT

- FLOATING DOCK

Marine ICCP Anodes & Ref.Cell

※ Scroll left / right to see the contents.

| Type of Anodes | Type of Andes | Material | Capacity (Max. Amp) |

|---|---|---|---|

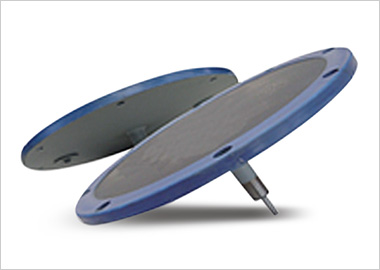

| Circular | SA440CM | MMO/Ti | 200 |

| SA400CM | MMO/Ti | 175 | |

| SA300CM | MMO/Ti | 125 | |

| SA200CM | MMO/Ti | 75 | |

| SA160CM | MMO/Ti | 25 | |

| SA440CP | Pt/Ti | 200 | |

| SA400CP | Pt/Ti | 175 | |

| SA300CP | Pt/Ti | 125 | |

| SA200CP | Pt/Ti | 75 | |

| SA160CP | Pt/Ti | 25 | |

| Linear | SA1200LM | MMO/Ti | 300 |

| SA820LM | MMO/Ti | 175 | |

| SA1200LP | Pt/Ti | 300 | |

| SA820LP | PT/Ti | 175 | |

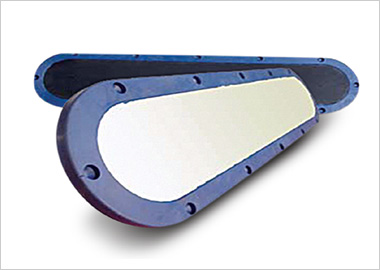

| Elliptical (Traditional Type) |

CA150EM | MMO/Ti | 150 |

| CA100EM | MMO/Ti | 100 | |

| CA75EM | MMO/Ti | 75 | |

| CA150EP | Pt/Ti | 150 | |

| CA100EP | Pt/Ti | 100 | |

| CA75EP | Pt/Ti | 75 | |

| Ref.Cell | SR45 | Pure Zinc | |

| Ref.Cell (Traditional Type) |

CR50E | Pure Zinc |

Advanced Type

-

Circular Anode

Circular Anode -

Linear Anode

Linear Anode -

Ref. Cellt

Ref. Cellt

Traditional Type

-

Circular Anode

Circular Anode -

Linear Anode

Linear Anode